Table of Contents

ToggleCondition Monitoring: An Introduction

In the intricate tapestry of modern life, industries play a pivotal role, churning out essentials like food, water, fuels, paper, and medicines. Behind the scenes, a symphony of machines tirelessly toils to make it all happen. However, these mechanical workhorses are not invincible; they face relentless wear and tear, often enduring harsh conditions.

In the best-case scenario, every machine will eventually falter. But what if there was a way to anticipate these failures, preventing lost production, costly repairs, and potential safety hazards? Enter the world of condition monitoring—a versatile toolkit designed to detect equipment issues at their inception.

By tailoring the right condition monitoring system to each unique situation, you can unveil critical faults as soon as they emerge, when repairs are more affordable and rapid. But that's not all; some condition monitoring technologies offer insights that extend beyond immediate problem-solving.

In this blog, we'll embark on a journey into the realm of condition monitoring, exploring how it can revolutionize industrial operations. Join us into this transformative technology and discover how it can enhance safety, efficiency, and sustainability for the long haul.

Making the Right Call: When to Implement Condition Monitoring

Condition monitoring is one such tool, and it's gaining increasing attention in the realm of industrial maintenance. But when should you reach for this tool, and when might it be better to stick with more traditional approaches?

At its core, condition monitoring involves the use of various sensors to measure physical features like current, lubricant quality, temperature, vibration, and voltage. These measurements help identify changes in a machine's behavior, providing early warnings of impending faults. It's the foundation of predictive maintenance, and when combined with recommended actions, it evolves into prescriptive maintenance. Proactive and reliability-centered maintenance encompass these condition-based strategies within their broader scope.

However, not every maintenance strategy is suited for every situation. Some, like "run to failure," make sense for non-critical equipment such as light bulbs and ceiling tiles. These low-cost items simply don't warrant the expense of more elaborate strategies.

So, when is condition monitoring the right choice? The answer is clear: when failure is not an option. Condition monitoring shines brightest when applied to critical machines whose breakdown could result in substantial financial losses, operational disruptions, or reputation damage (think sewage or chemical spills).

In short, “Condition monitoring.. it is for critical assets whose failure is costly.”

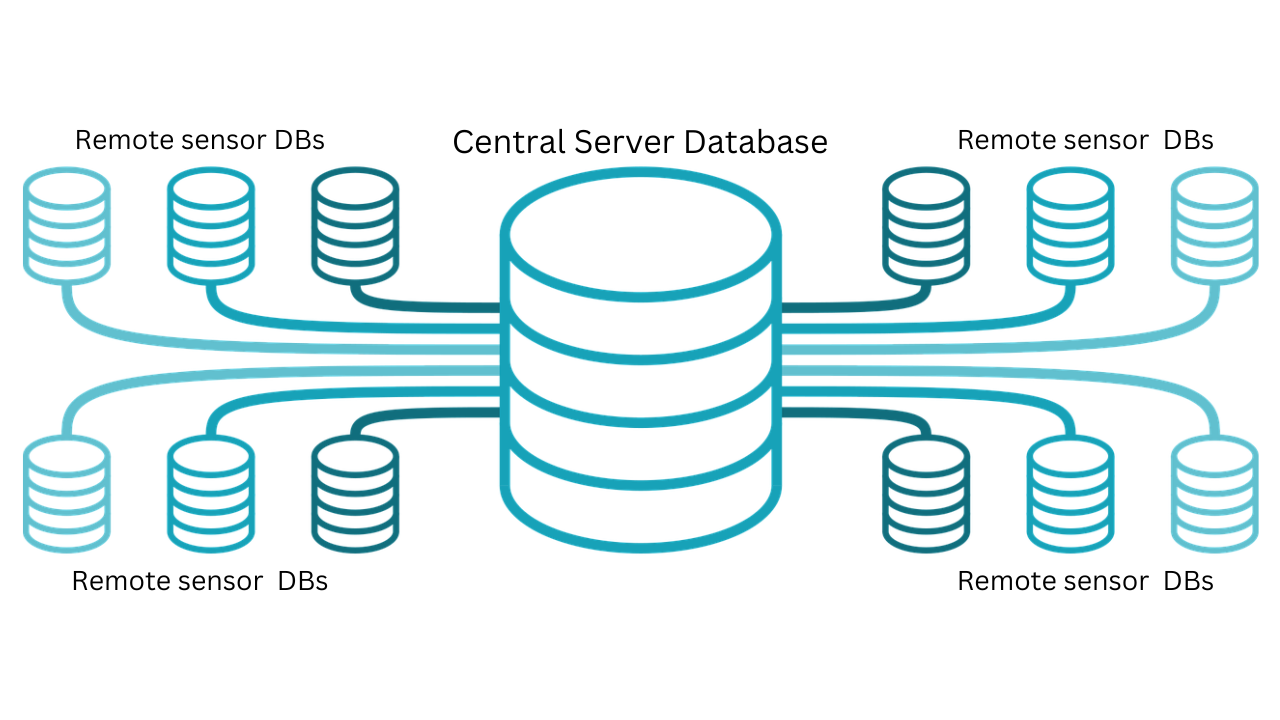

Traditionally, preventive maintenance based on schedules and machine redundancy with ample parts inventory have been reliable approaches to avoid critical failures. However, the landscape is shifting with the emergence of artificial intelligence and the industrial internet of things. With these technologies, modern condition monitoring can offer real-time, round-the-clock equipment health data analysis that rivals or even surpasses the effectiveness of traditional strategies, often at a lower cost.

The Power of Big Data: Predictive to Proactive Analytics

In the not-so-distant past, condition monitoring was a labor-intensive endeavor that relied heavily on manual data collection and the expertise of skilled human analysts. This traditional approach is still prevalent in many industries today, as the transition to digital manufacturing remains a complex journey. However, as we step into the 21st century, a game-changing alliance has emerged: the convergence of Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT). This union has reshaped the landscape of condition monitoring, offering compelling reasons to accelerate the shift towards digitalization.

In this era, traditional condition monitoring techniques are no longer limited to periodic checks conducted once a month or every six weeks. Instead, they can operate at astonishing speeds, collecting asset health data thousands of times per second, around the clock.

On the backend, machine learning algorithms process this data in real-time, swiftly identifying emerging faults and precisely pinpointing their origin. Whether it's a bearing, drive shaft, coupling, impeller, seal, intake, pulley, belt, stator, rotor, or countless other components, AI-based analysis excels in this domain.

AI brings a myriad of advantages to the table, surpassing human capabilities. These systems can process vast datasets at incredible speeds, constantly improving their knowledge base with every new piece of data, and always delivering conclusions rooted in factual evidence rather than intuition. As a result, AI-driven condition monitoring systems evolve over time, becoming more proficient at their task. With growing "failure machine data" libraries, they learn to associate patterns with their underlying causes, enabling proactive actions rather than merely predictive ones.

While periodic data collection and manual analysis remain valuable tools, critical systems demand a higher level of insight. Continuous monitoring empowered by AI and the IIoT has become the gold standard.

Different approaches of condition monitoring

Now we will discuss different approaches of condition monitoring techniques that provide a unique visual for machine health deviation. These approaches use measurement of current and voltage signals, Temperature of machine rotary parts, Vibration of machines, suspended particles in lubricant oil, and sound signals.

Electrical Signature Analysis (ESA):

ESA takes center stage in the world of continuous insight. It operates while the machine is running normally, earning its "online" status. ESA relies on a clever principle—analyzing the electrical power consumed by a running motor provides valuable information about the entire drive train.

Instead of placing sensors directly on the machine itself, ESA strategically positions sensors between the power supply and the machine. ESA employs various signal processing techniques to decode the electrical data. For instance, Motor Current Signature Analysis employs tools like the Fast Fourier Transform of Wavelet Transform to convert current signals into the frequency domain. It then scrutinizes changes in energy over time. Similarly, Motor Voltage Signature Analysis performs a similar transformation on voltage signals.

Power quality analysis, another facet of ESA, evaluates both current and voltage signals in the time domain, searching for phase variations, distortions, and balance issues. Remarkably, ESA can even extract lateral and torsional vibration data from the electrical signal, eliminating the need for additional sensors.

One notable feature of ESA is its non-invasive approach. The current and voltage sensors employed in ESA applications typically use clamps that attach around insulated wires, avoiding direct contact with the wire itself. These sensors come in various types, each harnessing different electromagnetic effects. For instance, inductive sensors capitalize on the relationship between current and magnetic fields, while Hall sensors exploit the induction of voltage across a current-carrying conductor in a magnetic field.

Temperature Sensors: From Thermocouples to Thermal Cameras

The world of temperature sensors is as diverse as it is fascinating, ranging from simple thermocouples that measure temperature at a single point to advanced infrared cameras that can create intricate heat maps covering entire areas. These sensors play a pivotal role in various applications, offering valuable insights into temperature-related dynamics.

Thermocouples and the Seebeck Effect: At the foundational level, thermocouples operate on the Seebeck effect—a captivating phenomenon where two wires made of different metals are connected at one end. When subjected to a change in temperature, these wires generate a voltage at their unjoined ends. This voltage serves as a telltale sign of temperature fluctuations. Thermocouples come in various combinations of metals, each with its unique temperature range. Furthermore, they are available in sheathed and unsheathed versions, depending on their exposure to environmental hazards such as corrosion and oxidation.

Infrared Cameras and Planck's Law: Stepping into the realm of advanced technology, we encounter infrared cameras, which rely on Planck's law. This fundamental principle states that any object with a temperature above absolute zero emits infrared radiation. The amount of emitted radiation increases with temperature. Infrared radiation falls within the same electromagnetic spectrum as ordinary light but operates at wavelengths beyond our visible range. This intriguing fact allows thermal cameras to capture thermal data. They come in both handheld and mounted configurations, with permanently installed options for real-time insights. However, it's worth noting that the accuracy of thermal cameras can be influenced by factors such as focus, surface reflectivity, air currents, and ambient temperature.

The Conversion and Interpretation Process: Within a thermal camera, the captured infrared signal undergoes a direct conversion into a color map. Each distinct color within the image represents a different temperature. To identify temperature-related changes over time, thermal analysis employs the techniques of computer vision—a branch of machine learning dedicated to image interpretation. In this domain, wavelets and Fourier transforms play a pivotal role in processing and deciphering the thermal data.

Vibrations in Condition Monitoring: Sensors and Signal Processing

Vibrations manifest as the rhythmic oscillations we commonly associate with the term "vibration." Much like acoustic stress wave sensors, vibration sensors are typically piezoelectric transducers, although resistive and capacitive versions also exist. These sensors serve various functions, some measuring displacement similar to acoustic sensors, while others gauge velocity or acceleration. Among these, piezoelectric accelerometers stand out as the preferred choice.

Additionally, sensors employing MEMS (Micro-Electronic Mechanical Systems) technology have gained popularity due to their compact size, cost-effectiveness, and the ability to integrate analysis capabilities directly into the device. However, they tend to be more susceptible to noise compared to their traditional counterparts.

To capture linear vibrations spanning all three directions (commonly referred to as triaxial vibrations), you have two options: either install three sensors, each dedicated to a single direction, or opt for a triaxial sensor capable of measuring vibrations in all three dimensions. For monitoring rotational vibrations, an angular sensor, often referred to as an encoder, is essential. If torsional vibrations are on your radar, consider installing two encoders.

When selecting a vibration sensor, pay careful attention to its frequency range, as this parameter is crucial for effective monitoring. Vibration analysis, like other condition monitoring techniques, performs signal processing in both the time and frequency domains. It employs algorithms such as the Fast Fourier Transform (FFT) and others to extract valuable insights from the collected data.

Lubricant Analysis Techniques used in conditional monitoring:

Atomic Emission Spectroscopy: This technique measures the presence and quantity of metals like iron, copper, and lead within the lubricant. Elevated levels of these metals are indicative of wear and can signal potential issues within the machinery.

Fourier Transform Infrared Spectroscopy: Employed to gauge levels of oxidation and aging in lubricants, this technique examines molecular changes that can impact the lubricant's effectiveness over time.

Karl Fischer Titration: This method quantifies the penetration of water into the lubricant. Water infiltration can lead to lubricant degradation and reduced performance, making it essential to monitor and control moisture levels.

Traditionally, these analytical procedures were conducted offline, involving the collection of lubricant samples from the machinery for subsequent laboratory analysis. However, recent advancements in sensor technology have revolutionized the field, enabling real-time, in-situ analysis of lubricants.

Today, sensors equipped with sophisticated technology can analyze lubricants directly within the machinery, providing instant feedback on their condition. This real-time approach enhances maintenance efficiency, as it allows for prompt corrective actions when irregularities are detected.

Stress Waves for Fault Detection

In the realm of fault detection, certain anomalies within materials, such as cracks, leaks, and fiber breakage, give rise to elastic waves, or stress waves, within the affected substance. This phenomenon is known as acoustic emission—a term employed in the scientific sense, distinct from our everyday perception of "sound" as audible vibrations in the air. In scientific terms, acoustics delves into the study of pressure waves propagating through solids, liquids, and gases. To avoid confusion, we'll continue to use the term "stress waves" throughout this blog post, emphasizing that acoustic pressure waves traverse not only air but also materials like concrete and metal, often at frequencies beyond the scope of human hearing.

Utilizing Acoustic Stress Waves

Acoustic stress waves prove to be a valuable data source for detecting a wide array of issues, including surface and near-surface cracks, pitting, delamination, and corrosion fatigue in materials like concrete, metal, and fiberglass. They are also adept at capturing phenomena like friction, crushing, and leakage. An especially noteworthy attribute of acoustic emissions is their capability to pinpoint the source of emerging faults. However, to achieve this, the deployment of multiple sensors is often necessary.

The analysis of acoustic emissions relies on advanced signal processing techniques, including the continuous wavelet transform, the Hilbert-Huang transform, as well as the short-time Fourier transform, and various Fourier variants. These techniques help extract meaningful information from the captured data.

Acoustic Emission Sensors

Typically, acoustic emission sensors are constructed as piezoelectric transducers. These sensors incorporate a crystal or ceramic element (hence the "piezo" prefix) to convert the minuscule surface displacement induced by stress waves—measured in nanometers—into an electric charge.

Furthermore, there are piezoresistive sensors, which gauge alterations in the electrical resistance of the crystal or ceramic caused by applied stress. Additionally, capacitive sensors measure changes in electrical capacitance, reflecting the sensor's ability to store electrical charge. A diverse array of sensor versions is available, each tailored to specific frequency ranges and other parameters.

Ultrasonic range sensors, for instance, excel in detecting low-energy stress sources amidst higher-energy structural vibrations and background noise. On another note, fiber optic sensors provide robust performance in environments with elevated temperatures and immunity to electromagnetic interference.

Conclusion: Elevating Industry Through Condition Monitoring

The timing of embracing condition monitoring is a strategic choice, reserved for those critical assets where failure is not an option. While traditional maintenance strategies held their ground, the emergence of artificial intelligence and the industrial internet of things has ushered in an era of real-time, data-driven analysis. Condition monitoring, armed with AI and the IIoT, provides continuous insight, transcending the limitations of periodic checks.

In our exploration, we've navigated through the diverse approaches of condition monitoring, each offering a unique perspective into machine health. From electrical signature analysis to temperature sensors, vibrations, and lubricant analysis, these techniques unveil the intricate nuances of industrial machinery, allowing for timely interventions and sustained performance.

As industries continue to evolve, condition monitoring stands as a beacon of innovation. It transcends mere maintenance; it empowers industries to embrace the future, confident in their ability to uphold reliability, efficiency, and sustainability. With condition monitoring, we embark on a journey towards a future where machines, like the industries they serve, stand resilient, robust, and ready to meet the challenges of tomorrow.