Here in this blog we will explore the types of industrial relays. Basically relays are electrical switches that are crucial components in various electrical systems, serving a fundamental role in controlling the flow of electricity. They act as intermediaries between input and output circuits, allowing for the automation and regulation of electrical processes. The importance of relays in modern control systems cannot be overstated, as they enable the efficient and reliable operation of a wide range of devices and equipment.

Table of Contents

ToggleImportance of industrial relays in modern control systems

Industrial relays play a vital role in controlling and directing electrical currents, ensuring that devices are powered on or off at the appropriate times. They serve as essential elements in complex control systems found in industries such as manufacturing, automotive, telecommunications, and more. Without relays, the automation and precision required in modern control systems would be difficult to achieve.

Relays provide the necessary functionality to manage electrical signals, making them indispensable components in the advancement of technology and the optimization of various processes. Their reliability, versatility, and ability to handle different voltage and current levels make them invaluable assets in today’s interconnected world of electrical engineering and automation.

What is a Relay? Types of Industrial Relays

A relay is an electrical device that acts as a switch to control the flow of electricity within a circuit. Its basic functionality involves the use of a low-power input signal to trigger the opening or closing of one or more larger electrical contacts, thereby allowing or interrupting the flow of current in a separate circuit. Relays are essential components in electrical systems where it’s necessary to control high-power or high-voltage circuits with low-power signals.

Definition and basic functionality

Industrial Relays consist of a coil, an armature, and one or more sets of contacts. When an electric current flows through the coil, it generates a magnetic field, which attracts the armature, causing the contacts to move and either make or break a connection.

The primary purpose of a relay is to isolate the control circuit (where the low-power signal operates) from the load circuit (where high-power devices or equipment are connected), providing electrical isolation and protection to the control system.

Historical background of Industrial Relays

The concept of industrial relays dates back to the early 19th century, where mechanical relays were initially developed for telegraphy applications. These early relays used electromagnets to control the opening and closing of contacts, enabling the transmission of electrical signals over long distances.

With advancements in technology, particularly in the fields of electrical engineering and telecommunications, relays evolved to meet the increasing demands of industrial automation, power distribution, and control systems.

Over time, the design and construction of industrial relays have undergone significant improvements, leading to the development of various types of industrial relays, including electromechanical relays, solid-state relays, and hybrid relays, each tailored to specific applications and performance requirements.

Construction of a Relay

Industrial Relays are constructed with precision and care to ensure reliable operation in various electrical applications. Understanding the components and structure of a relay is essential to grasp its functionality effectively.

Overview of industrial relay components and structure

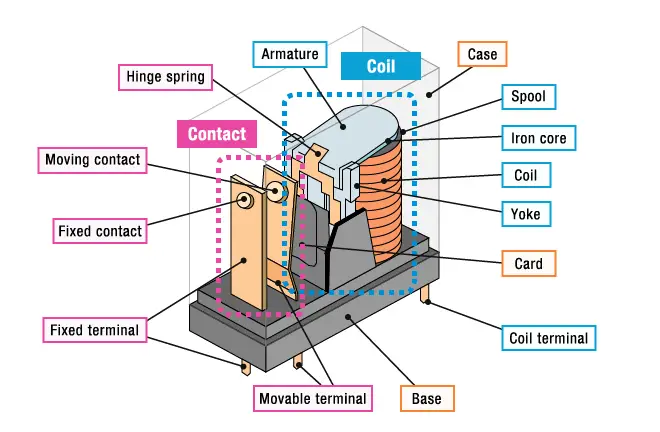

Coil: The coil is the primary component of a relay that generates a magnetic field when an electric current passes through it. This magnetic field is responsible for attracting the relay’s armature and actuating the switch contacts.

Armature: The armature is a movable component within the relay that is attracted by the magnetic field produced by the coil. Its movement is controlled by the energization of the coil, causing the contacts to open or close.

Contacts: The contacts are metallic terminals within the relay that make or break electrical connections when the relay is activated. These contacts come in various configurations, such as normally open (NO), normally closed (NC), or changeover (CO), depending on the relay’s design and intended application.

Terminals: Relays typically feature terminals for connecting external electrical wires or components. These terminals include the control input or coil terminals, common (COM) terminal, normally open (NO) terminal, and normally closed (NC) terminal, providing flexibility for wiring configurations.

Enclosure: Many industrial relays are housed within protective enclosures or casings to shield them from environmental factors such as dust, moisture, and mechanical damage. The enclosure also helps to contain electromagnetic interference and ensure the safety of the relay and surrounding components.

Explanation of key parts such as coils, terminals, and contacts

Coils: The coil serves as the input to the relay, receiving a low-power signal that energizes it and creates a magnetic field. This magnetic field then attracts the armature, initiating the switching action of the contacts.

Terminals: Relays feature multiple terminals for connecting external circuits. The control input or coil terminals receive the input signal, while the common (COM) terminal serves as a connection point for both the normally open (NO) and normally closed (NC) contacts.

Contacts: The contacts are the switch elements of the relay, responsible for making or breaking electrical connections. When the relay is activated, the contacts move to their respective positions based on the relay’s design, allowing current to flow or interrupt within the load circuit.

Terminals Of Relay

Relays feature several terminals that serve specific functions in controlling electrical circuits. Understanding these terminals is crucial for proper installation and operation of industrial relays in various applications.

Control Input or Coil Terminals:

The control input or coil terminals are where the input signal is applied to energize the relay. When a voltage is applied across these terminals, it activates the relay coil, creating a magnetic field that causes the relay to switch its contacts. These terminals are typically labeled as (+) and (-) or with corresponding symbols to indicate the polarity of the input signal.

COM or Common Terminal:

The common (COM) terminal serves as a central connection point within the relay. It is typically used to connect one side of both the normally open (NO) and normally closed (NC) contacts. When the relay is not energized, the common terminal is connected to the NC terminal, and when the relay is energized, it switches to the NO terminal.

NO Terminal (Normally Open):

The normally open (NO) terminal is one of the contact terminals within the relay. When the relay is not energized, the NO terminal is disconnected from the common (COM) terminal. However, when the relay coil is energized, the contacts move to establish a connection between the NO terminal and the common terminal, allowing current to flow through the circuit.

NC Terminal (Normally Closed):

The normally closed (NC) terminal is another contact terminal within the relay. In its default state, when the relay is not energized, the NC terminal is connected to the common (COM) terminal, allowing current to flow through the circuit. When the relay coil is energized, the contacts move to break this connection, interrupting the flow of current.

Poles and Throw:

The terms “poles” and “throw” describe the configuration of the contacts within the relay. A pole refers to a set of contacts that are controlled simultaneously by the relay coil. The throw refers to the number of positions the contacts can take: single throw (ST) or double throw (DT). For example, a single pole single throw (SPST) relay has one set of contacts that can be in one of two positions (open or closed), while a double pole double throw (DPDT) relay has two sets of contacts that can each be in one of two positions.

Understanding the terminals of industrial relays help in correctly wiring and configuring the relay for specific applications. By utilizing these terminals effectively, relays can efficiently control electrical circuits, providing essential switching functionality in various systems and devices.

Relay Operation

Industrial Relays are integral components in electrical systems, facilitating the control and switching of electrical circuits. Understanding how relays operate and execute their switching functions is crucial for comprehending their role in various applications.

How relays operate and switch electrical circuits

Input Signal Activation: The operation of a relay begins with the application of an input signal to the coil terminals. This input signal can be in the form of a voltage or current, depending on the relay’s specifications. When the input signal reaches a certain threshold, it energizes the coil, generating a magnetic field around it.

Magnetic Field Generation: As the coil becomes energized, it produces a magnetic field that attracts the relay’s armature. The armature is typically connected to a movable contact, which changes its position in response to the magnetic force exerted by the coil.

Contact Movement: The movement of the armature causes the relay contacts to switch positions. Depending on the relay type and configuration, this action can either establish or break electrical connections within the circuit. For example, in a normally open (NO) relay, the contacts close to complete the circuit when the relay is energized, whereas in a normally closed (NC) relay, the contacts open to interrupt the circuit.

Sequence of events during relay operation:

Input Signal Application: A voltage or current signal is applied to the coil terminals of the relay, initiating the activation process.

Coil Energization: The input signal energizes the coil, creating a magnetic field around it. This magnetic field attracts the armature towards the coil.

Contact Movement: As the armature moves, it causes the relay contacts to switch positions. In a normally open (NO) relay, the contacts close to establish electrical continuity, whereas in a normally closed (NC) relay, the contacts open to interrupt the circuit.

Circuit Control: The switching action of the relay contacts controls the flow of current within the circuit, either allowing it to pass through (when the contacts close) or blocking it (when the contacts open). This enables the relay to perform its intended function, such as turning on/off a load or redirecting the current flow.

Deactivation: When the input signal to the coil is removed or falls below the threshold level, the coil is de-energized, and the magnetic field dissipates. As a result, the armature returns to its original position, and the relay contacts revert to their default state, ready for the next operation cycle.

Types of Industrial Relays

Industrial Relays come in various types, each designed to suit specific applications and operational requirements. Understanding these types is essential for selecting the appropriate relay for a particular task. Here’s a breakdown of the different types of relays:

Types of Industrial Relays Based on Poles and Throw:

SPST Relay (Single Pole Single Throw): This type of relay consists of a single set of contacts that can either be in the open or closed position.

SPDT Relay (Single Pole Double Throw): SPDT relays feature a single set of contacts that can be connected to one of two other terminals, allowing for switching between two different circuits.

DPST Relay (Double Pole Single Throw): DPST relays have two sets of contacts, each capable of connecting to one terminal, effectively doubling the switching capacity compared to SPST relays.

DPDT Relay (Double Pole Double Throw): DPDT relays contain two sets of contacts, each capable of connecting to one of two terminals, providing double the switching capacity of SPDT relays.

Types of Industrial Relays Based on Forms:

“Form A” Relay: This refers to a relay with a normally open contact configuration.

“Form B” Relay: “Form B” relays feature a normally closed contact configuration.

“Form C” Relay: “Form C” relays incorporate both normally open and normally closed contacts.

“Form D” Relay: “Form D” relays consist of multiple contacts arranged in various configurations for specific switching applications.

Types of Industrial Relays Based On Operation Principles:

EMR (Electromechanical Relay): EMRs utilize electromagnetic principles to operate the switching mechanism. They are versatile and widely used in various applications.

SSR (Solid State Relay): SSRs rely on semiconductor devices such as transistors or thyristors to switch electrical circuits. They offer advantages like faster switching speeds and longer lifespan compared to EMRs.

Reed Relay: Reed relays use a small hermetically sealed glass tube containing two metal reeds as the switch mechanism. They offer high reliability and are commonly used in telecommunications and test equipment.

Electrothermal Relay (Thermal Relay): Thermal relays operate based on the principle of temperature change to trigger the switching action. They are often used in motor protection circuits.

Types of Industrial Relays – Polarized and Non-polarized Relay:

Polarized Relay: Polarized relays have a specific orientation for their coil terminals, ensuring proper operation. They are commonly used in applications where polarity is crucial.

Non-polarized Relay: Non-polarized relays do not have specific coil terminal orientations and can be connected without regard to polarity. They offer simplicity and flexibility in wiring arrangements.

Each type of industrial relay offers unique advantages and capabilities, catering to a wide range of electrical control and switching needs.

Application Of Industrial Relay

Industrial Relays find extensive use across diverse industries and applications due to their versatility and reliability in controlling electrical circuits. Here are some common applications of relays:

Industrial Automation and Control Systems:

Relays play a critical role in industrial automation by controlling various processes and machinery. They enable the automation of production lines, robotic systems, and manufacturing equipment.

In control systems, relays are used to regulate the operation of motors, solenoids, valves, and other devices, ensuring precise and efficient operation.

Relays provide safety interlocking features, emergency shutdowns, and fault protection in industrial environments, enhancing operational safety and preventing equipment damage.

Power Distribution and Protection:

Industrial Relays are integral to power distribution systems, where they control the flow of electricity and manage load distribution across different circuits.

In electrical substations and distribution panels, relays are employed for fault detection, overload protection, and isolation of faulty equipment to prevent damage to the electrical grid.

Protection relays monitor parameters such as voltage, current, and frequency, and initiate corrective actions such as tripping circuit breakers in case of abnormalities, safeguarding equipment and preventing power outages.

Automotive Industry:

Industrial Relays are widely used in automotive systems for controlling lighting, heating, ventilation, air conditioning (HVAC), wipers, and other electrical components.

In vehicle engine management systems, relays regulate the operation of fuel injectors, ignition systems, and cooling fans, ensuring optimal engine performance.

Automotive relays provide overload protection, short circuit protection, and voltage regulation, enhancing the safety and reliability of vehicle electronics.

Home Automation and IoT Devices

Industrial Relays form the backbone of home automation systems, enabling remote control and automation of lighting, heating, security cameras, and smart appliances.

In Internet of Things (IoT) devices, relays facilitate connectivity and interoperability between sensors, actuators, and control units, allowing for seamless integration into smart home ecosystems.

Home automation relays offer energy-saving features, scheduling capabilities, and remote monitoring and control via smartphone apps or voice assistants, enhancing convenience and energy efficiency in residential settings.

Industrial Relays continue to play a vital role in enabling automation, safety, and efficiency across a wide range of applications, from industrial processes to consumer electronics. Their adaptability and reliability make them indispensable components in modern electrical and control systems, driving innovation and technological advancement in various industries.

Conclusion

Industrial Relays play a crucial role in modern electrical and control systems, serving as indispensable components in various applications. Their importance stems from their ability to efficiently control the flow of electricity, providing essential switching functionality that enables automation, protection, and regulation of electrical circuits.

In industrial automation and control systems, relays are utilized to control machinery, monitor processes, and ensure safety through precise and reliable switching actions. They facilitate the integration of sensors, actuators, and other devices, enabling sophisticated control strategies that optimize production efficiency and quality.

In home automation and IoT devices, relays enable remote control and automation of household appliances, lighting, HVAC systems, and security systems. They form the backbone of smart home technologies, allowing homeowners to monitor and control their environment conveniently and efficiently.

In conclusion, the importance of relays in modern electrical and control systems cannot be overstated. Their versatility, reliability, and ability to handle diverse switching tasks make them indispensable components in a wide range of industries and applications. As technology continues to advance, relays will remain essential for achieving efficient and precise control over electrical circuits, driving innovation and progress in various fields.

Reference: IEC Standard for relay construction

Explore more for other Components of Industrial Automation