In the vast landscape of technology and automation, there are different types of control systems and the role of control systems is paramount. From the operation of everyday devices to the intricacies of industrial processes, control systems play a pivotal role in regulating and optimizing performance. This blog aims to delve into the heart of control systems, shedding light on their various types and applications. Let’s embark on this journey by laying the groundwork for a comprehensive understanding.

Table of Contents

ToggleDefinition of Control Systems

Control systems, in essence, refer to a set of devices or mechanisms that manage, regulate, and command the behavior of other devices or systems. These systems are designed to ensure a desired output or performance by manipulating the input signals. In simpler terms, they act as the orchestrators behind the scenes, ensuring that the intended outcomes are achieved efficiently and precisely.

Importance of Control Systems in Various Industries

The significance of control systems extends across a myriad of industries, influencing the way processes are managed and devices operate. In manufacturing, control systems are the linchpin of production lines, optimizing efficiency and maintaining product quality. In aerospace, they govern the flight dynamics of aircraft, ensuring a safe and controlled journey. Even in everyday life, from thermostat controls in homes to cruise control in automobiles, these systems enhance convenience and performance.

The impact of control systems on industries can be distilled into a few key points:

Precision and Accuracy: Control systems enable precise regulation, ensuring that processes and devices operate with a high level of accuracy.

Efficiency: By automating and regulating processes, control systems contribute to increased efficiency, reducing waste and improving overall productivity.

Safety: In critical industries such as nuclear power plants or chemical manufacturing, control systems are instrumental in maintaining safety by preventing accidents and responding to emergencies.

As we navigate through the blog, our primary focus will be on understanding the diverse landscape of control systems. We will explore various types, ranging from traditional analog control systems to cutting-edge technologies like edge control systems. Each type possesses unique characteristics and finds applications in specific domains.

Types of Control Systems

As we delve into the intricate realm of control systems, it’s essential to explore the various types that form the backbone of automation and regulation. This section will provide a detailed examination of Analog Control Systems, Digital Control Systems, Embedded Control Systems, and Remote Control Systems.

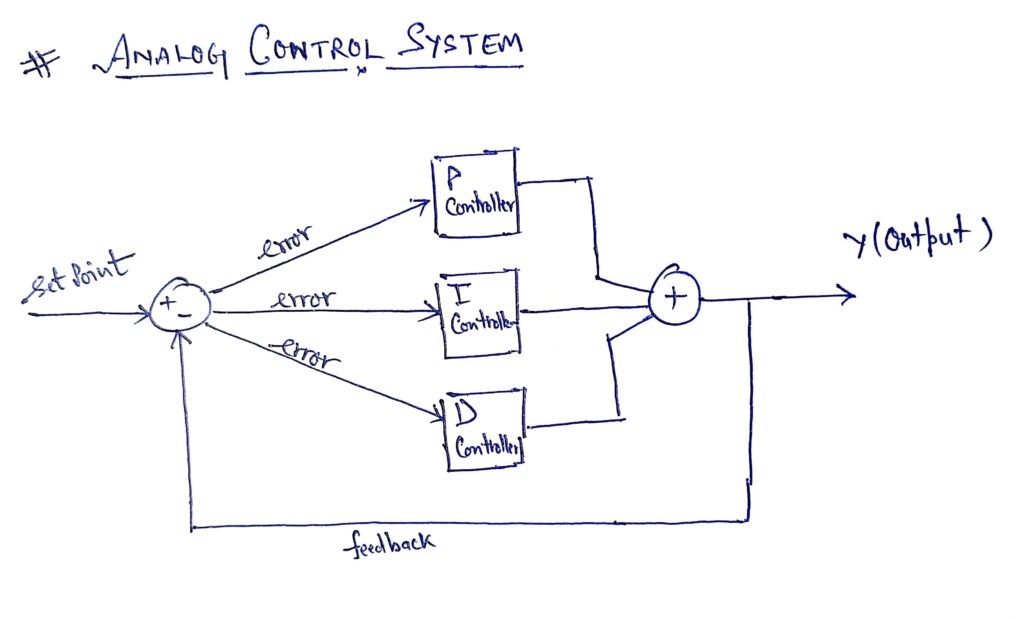

Types of Control Systems: Analog Control System

Analog control systems operate on continuous signals, employing components such as operational amplifiers, resistors, and capacitors. These systems manipulate signals in a smooth, continuous manner to regulate the output.

Analog control systems find applications in diverse industries, including aerospace, automotive, and manufacturing. Their ability to provide a continuous response makes them suitable for processes where precision is crucial.

Examples of Analog Control Systems

Thermostats: Analog control regulates temperature by continuously adjusting the heating or cooling mechanism.

Motor Speed Controllers: Used in industrial settings to maintain a consistent rotational speed in motors.

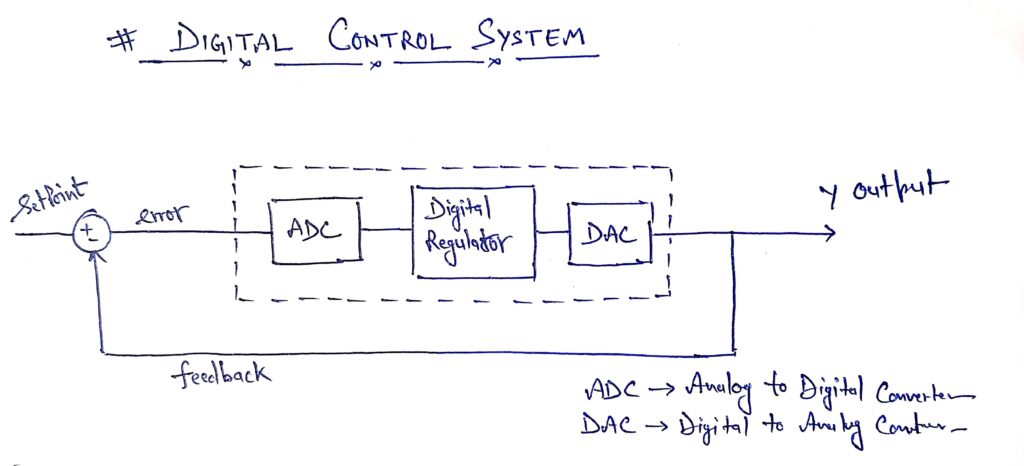

Types of Control Systems: Digital Control System

Digital control systems process discrete signals represented by binary code (0s and 1s). They utilize digital components like microcontrollers and digital signal processors for signal processing.

Advantages Over Analog Control Systems

Precision: Digital systems offer precise control and are less susceptible to signal degradation.

Flexibility: Easy implementation of complex algorithms and adaptability to varying conditions.

Applications and Examples

Industrial Automation: Digital control systems are integral in controlling manufacturing processes.

Digital Thermostats: Offer more precise temperature control than their analog counterparts.

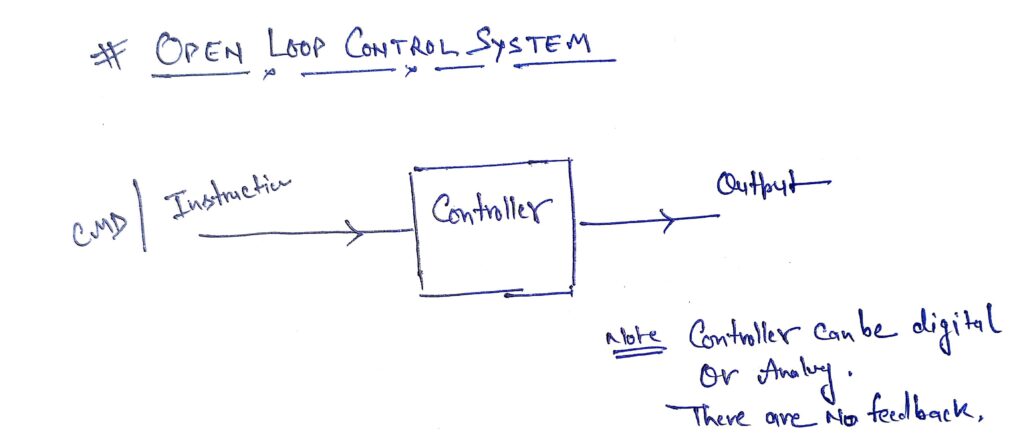

Types of Control Systems: Open-Loop Control System

An open-loop control system, also known as a non-feedback or uncontrolled system, operates without real-time feedback. It relies on a predefined input to generate a specific output, without actively monitoring the actual output.

No Feedback: Open-loop systems lack the mechanism to adjust the output based on the actual performance.

Predictable Output: The output is entirely determined by the input and the system’s characteristics.

Simple Design: Open-loop systems are generally simpler in design and implementation.

Applications of open-loop control system

Toasters: A simple example is a toaster, where the heating element operates based on a preset timer. The toasting process occurs without considering the actual state of the bread.

Traffic Light Control: Traffic lights often operate in an open-loop fashion, following predetermined time patterns without actively responding to the current traffic conditions.

Types of Control Systems: Closed-Loop Control System

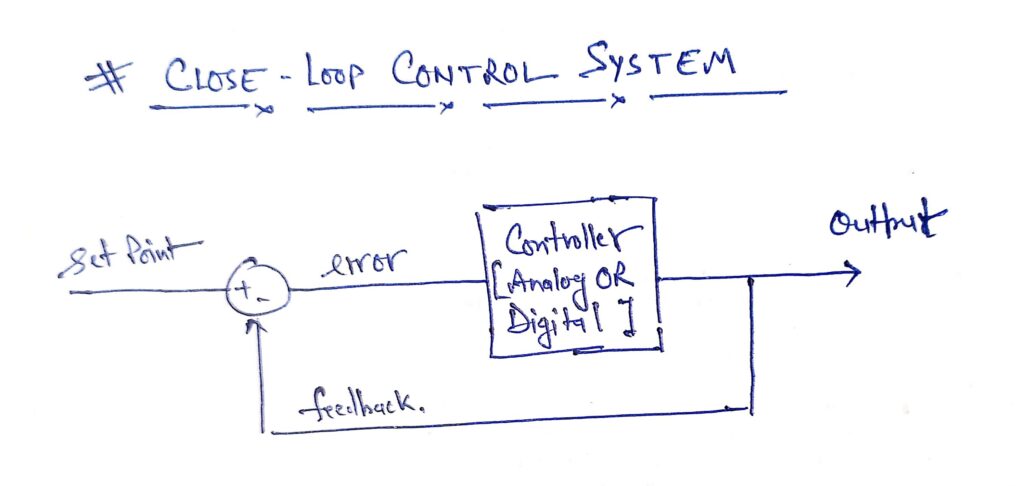

A closed-loop control system, also known as a feedback or controlled system, actively monitors the output and adjusts the input in real-time to maintain the desired output.

Feedback Mechanism: Closed-loop systems incorporate sensors to continuously measure the output and provide feedback to the controller.

Dynamic Adjustment: The input is dynamically adjusted based on the feedback, ensuring the system responds to changes and disturbances.

Greater Stability: Closed-loop systems tend to be more stable and accurate compared to open-loop systems.

Applications closed-loop control system

Temperature Control Systems: Thermostats in HVAC systems use closed-loop control to maintain a set temperature.

Speed Control in Vehicles: Cruise control systems adjust the throttle based on the actual vehicle speed, ensuring it remains constant.

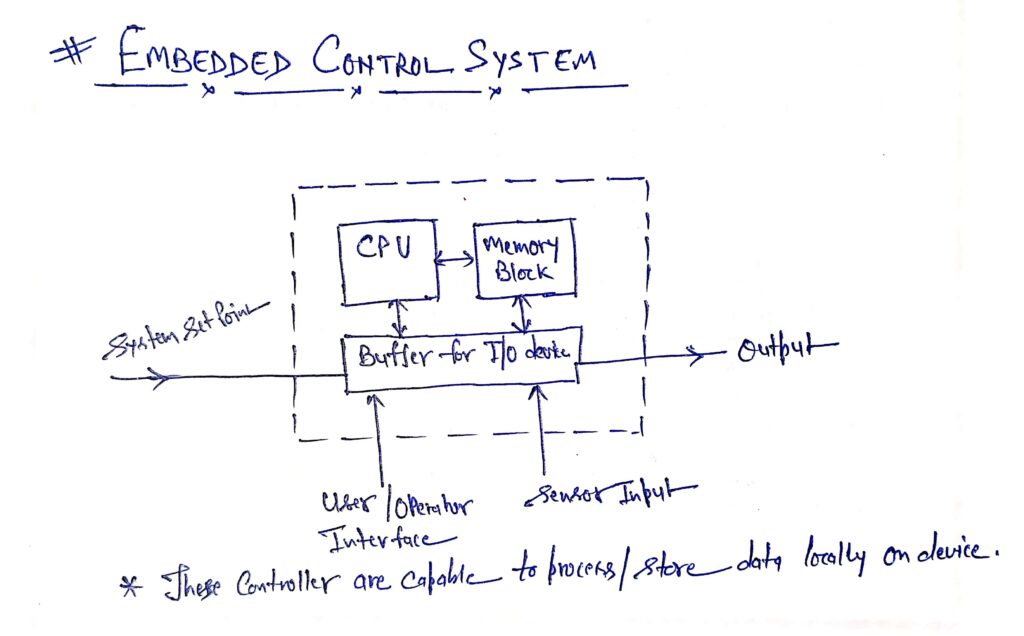

Types of Control Systems: Embedded Control System

Embedded control systems are integrated into larger systems or devices. They consist of a central processing unit (CPU) and input/output interfaces, with control functions embedded in the hardware.

Examples in Everyday Devices for different types of control systems

Washing Machines: Embedded systems control washing cycles, water temperature, and spin speed.

Smartphones: Utilize embedded control systems for touch screen responsiveness and overall device functionality.

Embedded systems are the backbone of modern technology, enabling the seamless operation of various devices and ensuring precise control in real-time.

Types of Control Systems: Remote Control System

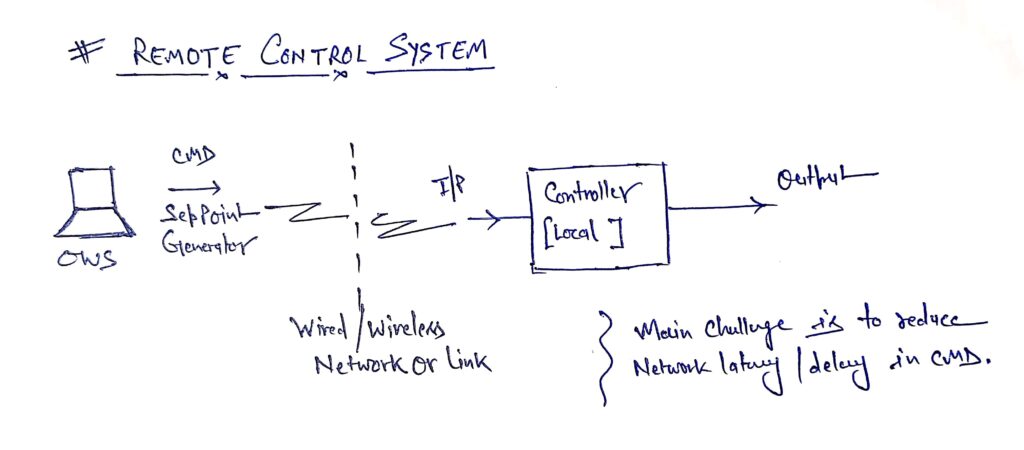

Remote control systems enable the operation of devices from a distance. This is achieved through various means such as radio frequency (RF) or infrared (IR) signals.

Applications in Consumer Electronics and Industry

TV Remote Controls: Widely used for changing channels, adjusting volume, and controlling various TV functions.

Industrial Processes: Remote control is employed in industries for operating machinery in hazardous or hard-to-reach locations.

In the subsequent sections, we will further explore edge control systems and additional types of control systems, providing a comprehensive understanding of the diverse technologies shaping our automated world.

#Read more about Turbine Control System

Types of Control Systems: Edge Control System

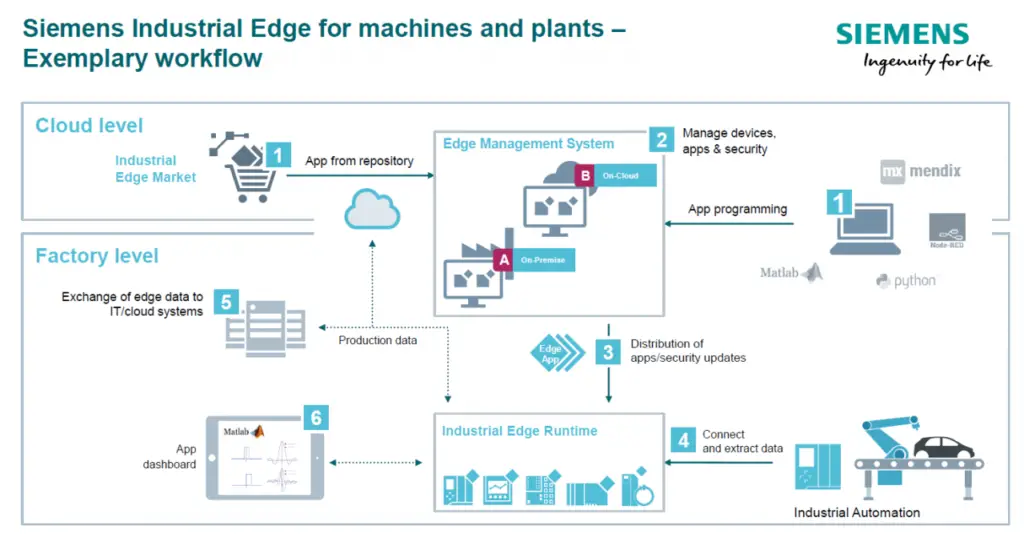

In the ever-evolving landscape of control systems, the emergence of Edge Control Systems has marked a paradigm shift in the way data is processed and decisions are made. Let’s explore the key aspects of these systems, from their foundational principles to their pivotal role in real-time processing and applications in the realms of the Internet of Things (IoT) and industrial automation.

Edge computing involves processing data near the source of data generation rather than relying solely on centralized servers. This approach aims to reduce latency, enhance efficiency, and address the challenges posed by the massive influx of data in contemporary systems.

Key Components of edge control system

Edge Devices: Devices equipped with processing capabilities, such as sensors, controllers, or gateways.

Edge Servers: Computing devices located closer to the data source for real-time processing.

Edge Networks: High-speed, localized networks facilitating communication between edge devices and servers.

Role of Edge Control Systems in Real-time Processing

Real-time Decision Making:

Edge Control Systems play a crucial role in enabling real-time decision-making at or near the source of data. By processing data locally, these systems minimize the delay associated with transmitting data to a centralized server for analysis.

Latency Reduction:

The proximity of edge devices to the data source significantly reduces latency, ensuring rapid responses. This is particularly vital in applications where immediate decision-making is critical, such as autonomous vehicles, smart grids, and healthcare systems.

Enhanced Privacy and Security:

Edge computing enhances data privacy and security by minimizing the need to transmit sensitive information to external servers. This localized approach mitigates the risks associated with data transfer over external networks.

Types of Control Systems: Nonlinear Control System

Nonlinear control systems deal with systems where the relationship between the input and output is nonlinear. Unlike linear systems, these systems exhibit complex behaviors and may not follow a straightforward cause-and-effect pattern. Nonlinear control strategies are employed to address these intricate dynamics.

Applications of Nonlinear control systems :

Biological Systems: Nonlinear control is often used to model and regulate biological systems where responses may not be linear.

Aerospace: Nonlinear control finds applications in the control of aircraft and spacecraft, addressing the complexities of aerodynamics and flight dynamics.

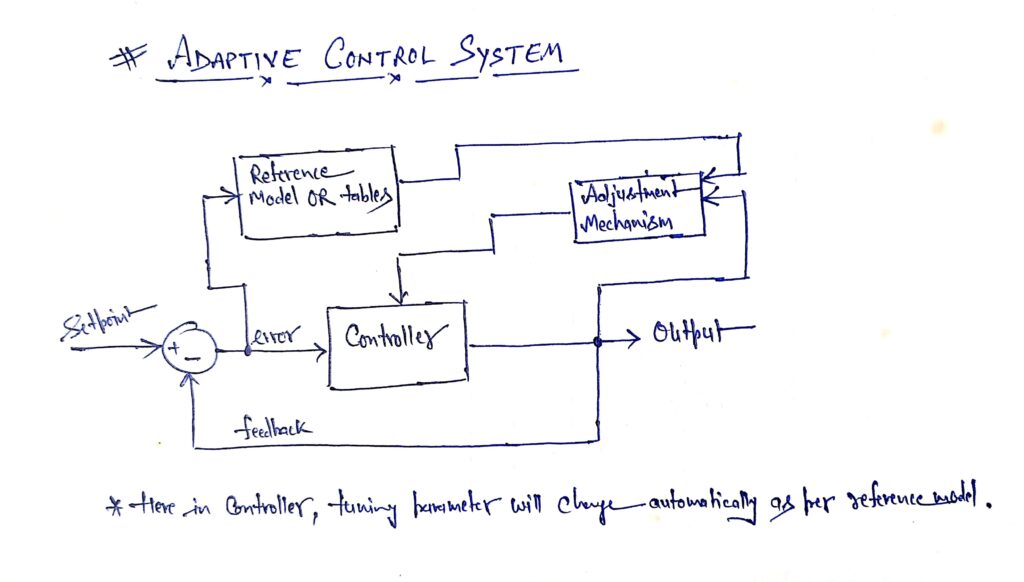

Types of Control Systems: Adaptive Control System

Adaptive control systems adjust their parameters in real-time based on changes in the system or its environment. These systems are designed to adapt to varying conditions and uncertainties, making them highly versatile in dynamic environments.

Applications of Adaptive control systems:

Automotive Control: Adaptive control is used in vehicles to adjust parameters such as engine performance based on driving conditions.

Process Control: In industries where operating conditions may change, adaptive control ensures optimal performance despite uncertainties.

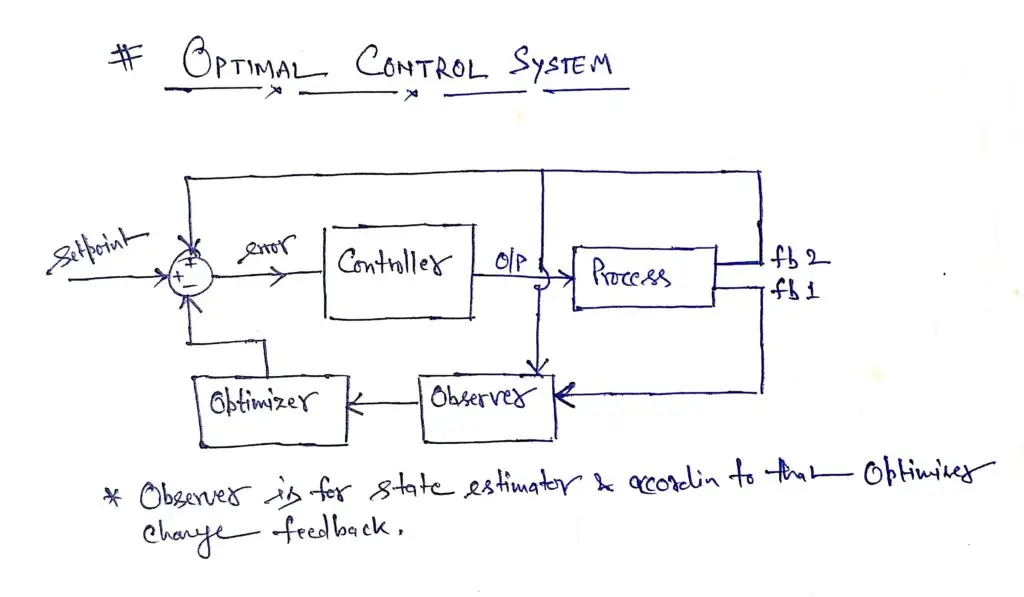

Types of Control Systems: Optimal Control System

Optimal control systems aim to minimize or maximize a certain performance criterion. These systems determine the best control input over time to achieve the desired outcome, taking into account constraints and system dynamics.

Applications of Optimal control systems:

Robotics: Optimal control is employed in robotics to optimize movements and achieve precise control of robotic arms.

Economic Systems: Optimal control strategies are utilized in economic models to maximize profit or minimize cost under various constraints.

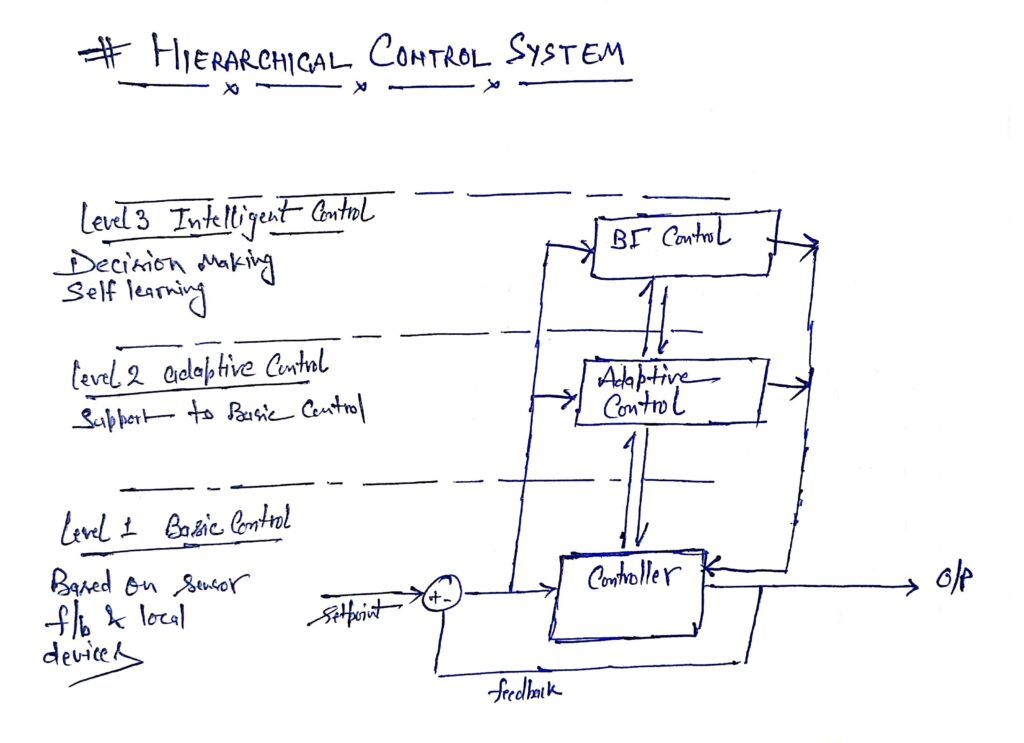

Types of Control Systems: Hierarchical Control System

Hierarchical control systems involve multiple levels of control, each responsible for different aspects of the system. This hierarchical structure helps in managing complexity and organizing control tasks.

Applications of Hierarchical control systems:

Manufacturing Plants: Hierarchical control is used in manufacturing plants, where different levels of control manage everything from high-level decision-making to low-level device control.

Traffic Control Systems: Traffic management systems often employ hierarchical control to optimize traffic flow and respond to changing conditions.

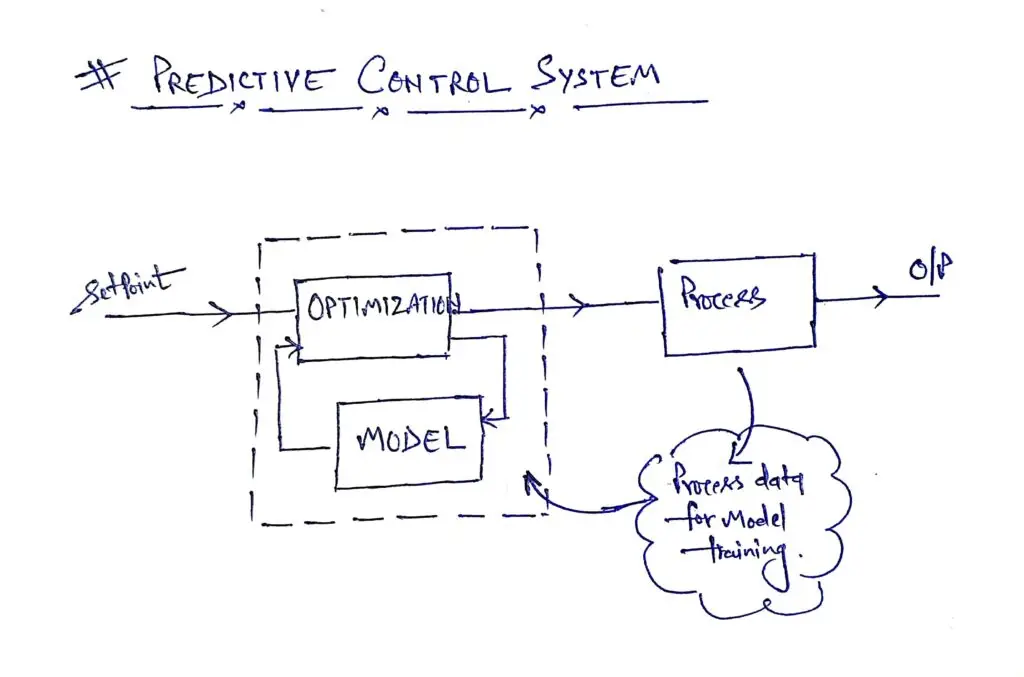

Types of Control Systems: Predictive Control System

Predictive control systems utilize models of the system to predict its future behavior and optimize control inputs based on these predictions. These systems are particularly adept at handling complex and dynamic processes.

Applications Predictive control systems:

Process Industries: Predictive control is used in chemical plants and refineries to optimize production processes and maintain product quality.

Energy Management: Predictive control strategies are applied in smart grids to optimize energy distribution and consumption.

Factors Influencing Control System Selection

System Characteristics:

Understanding the dynamics, linearity or nonlinearity, and time delays of the system is crucial. Different control systems are better suited for specific system behaviors.

Precision Requirements:

The level of precision required in controlling the system is a key factor. Applications demanding high precision may benefit from digital control systems.

Response Time:

The time it takes for a control system to respond to changes in the input or disturbance is critical. Real-time applications often require faster response times, favoring systems like edge control.

Complexity of the Process:

The complexity of the process being controlled influences the choice of a control system. Complex processes might benefit from predictive or hierarchical control.

Cost Constraints:

Budget considerations play a significant role. Analog control systems may be cost-effective for certain applications, while advanced systems like predictive control may involve higher costs.

Watch our video on Different type of control system.

Conclusion

In conclusion, the world of control systems is a dynamic and ever-evolving domain. The choices we make in selecting and implementing these systems shape the efficiency, safety, and sustainability of the technologies that underpin our interconnected world. As we continue to push the boundaries of technological innovation, the role of control systems will remain central, steering us toward a future where automation is not just efficient but also adaptive, secure, and environmentally conscious.

FAQ: Control Systems Types

Q1: What is the fundamental definition of control systems?

A: Control systems refer to a set of devices or mechanisms designed to manage, regulate, and command the behavior of other devices or systems. They ensure a desired output or performance by manipulating input signals.

Q2: Why are control systems important in various industries?

A: Control systems play a crucial role in optimizing efficiency, maintaining product quality, and ensuring safety across diverse industries. They enable precise regulation, increase efficiency, and contribute to overall productivity.

Q3: Can you provide examples of the impact of control systems in everyday life?

A: Certainly! Examples include thermostat controls in homes, cruise control in automobiles, and various consumer electronics. These systems enhance convenience and performance in daily activities.

Q4: What are the key characteristics of analog control systems?

– A: Analog control systems operate on continuous signals, utilizing components like operational amplifiers. They find applications in industries where a smooth and continuous response is crucial for precision.

Q5: How do digital control systems differ from analog ones?

A: Digital control systems process discrete signals represented by binary code. They offer advantages such as precise control, flexibility in implementing complex algorithms, and adaptability to varying conditions.

Q6: What is the role of embedded control systems in modern technology?

A: Embedded control systems, integrated into devices, act as the backbone of modern technology. They ensure seamless operation, precise control in real-time, and are found in devices like washing machines and smartphones.

Q7: How do remote control systems operate, and where are they commonly used?

A: Remote control systems enable device operation from a distance through radio frequency or infrared signals. They are widely used in consumer electronics like TV remote controls and in industries for operating machinery remotely.

Q8: What defines edge control systems, and how do they contribute to real-time processing?

A: Edge control systems involve processing data near the source of generation, reducing latency. They utilize devices, servers, and networks to enable real-time decision-making, crucial in applications like autonomous vehicles and smart grids.

Q9: Can you explain the key characteristics and applications of nonlinear control systems?

A: Nonlinear control systems deal with complex system behaviors where the input-output relationship is nonlinear. They find applications in biological systems and aerospace for addressing intricate dynamics.

Q10: How do adaptive control systems adjust to changing conditions, and where are they commonly applied?

A: Adaptive control systems adjust parameters in real-time based on changes in the system. They are applied in automotive control for adjusting engine performance and in process industries to ensure optimal performance despite uncertainties.

Q11: What sets optimal control systems apart, and where are they applied?

A: Optimal control systems aim to minimize or maximize a performance criterion. They find applications in robotics for optimizing movements and in economic systems to maximize profit or minimize cost.

Q12: What characterizes hierarchical control systems, and where are they commonly used?

A: Hierarchical control systems involve multiple control levels, managing different aspects of the system. They are used in manufacturing plants for decision-making and in traffic control systems for optimizing traffic flow.

Q13: How do predictive control systems operate, and in which industries are they applied?

A: Predictive control systems use models to predict future system behavior and optimize control inputs. They are applied in process industries for optimizing production processes and in energy management for smart grids.

Q14: What factors influence the selection of a control system for a specific application?

A: Factors include system characteristics, precision requirements, response time, complexity of the process, and cost constraints. The choice depends on the specific needs and dynamics of the application.

Q15: How does the conclusion summarize the role of control systems in our interconnected world?

A: The conclusion emphasizes that control systems shape the efficiency, safety, and sustainability of technologies. It underscores the dynamic and ever-evolving nature of control systems, steering us toward a future of efficient, adaptive, secure, and environmentally conscious automation.

Explore different types of control systems / product used in industry

https://www.aveva.com/en/products/control-systems-and-simulators/

#different types of control systems, *different types of control systems