Temperature switch Calibration is a critical aspect of ensuring the accuracy and reliability of temperature measurement and control systems. Temperature switches play a vital role in various industrial applications, where precise temperature monitoring is essential for maintaining process integrity, product quality, and safety. Calibration involves verifying the performance of temperature switches against known reference standards, adjusting them as necessary, and documenting the results to demonstrate compliance with regulatory requirements and industry standards. In this blog, we will explore the importance of temperature switch calibration, the calibration process, and best practices for achieving accurate temperature measurements in diverse operational environments.

Table of Contents

ToggleTemperature Switch Calibration Procedure

Brief Explanation of a Temperature Switch:

A temperature switch is an electrical device designed to open or close a circuit based on temperature fluctuations. It is commonly used in various industrial and domestic applications to control processes or equipment based on temperature conditions.

Importance of Calibration for Accurate Temperature Measurements:

Calibration is crucial for ensuring the accuracy and reliability of temperature switches. Without proper calibration, temperature switches may provide inaccurate readings, leading to inefficient operation or potential safety hazards. Calibration helps to verify the performance of temperature switches and ensures they operate within specified tolerances.

Overview of the Temperature Switch Calibration Procedure:

The calibration procedure involves a series of steps to verify and adjust the temperature switch’s response to temperature changes. It includes preparation, inspection, setting up calibration equipment, performing calibration, verification of results, and documentation. Following a standardized calibration procedure is essential to maintain the functionality and accuracy of temperature switches.

Understanding Temperature Switches

Definition and Function of Temperature Switches:

Temperature switches are devices that are sensitive to changes in temperature and are designed to either open or close an electrical circuit at a specific temperature threshold. They serve as automatic control mechanisms, regulating various processes or equipment based on temperature conditions.

Refer: Danfoss Temperature Switches

Types of Temperature Switches and Their Applications:

There are several types of temperature switches available, including bimetallic, gas-filled, and electronic temperature switches. Each type has its unique operating principles and applications:

Bimetallic Temperature Switches: These switches use the differential expansion of two different metals to actuate a mechanical switch. They are commonly used in household appliances, HVAC systems, and industrial machinery.

Gas-Filled Temperature Switches: These switches utilize the thermal expansion of a gas to trigger a switch mechanism. They are often employed in automotive cooling systems, refrigeration units, and process control applications.

Electronic Temperature Switches: These switches utilize electronic sensors, such as thermistors or RTDs (Resistance Temperature Detectors), to detect temperature changes and trigger electronic switching circuits. They are prevalent in digital temperature control systems, medical devices, and laboratory equipment.

Importance of Accurate Temperature Sensing in Various Industries

Accurate temperature sensing is critical across numerous industries for maintaining quality, safety, and efficiency in processes. In industries such as manufacturing, pharmaceuticals, food and beverage, and automotive, precise temperature control is essential to ensure product quality, optimize production processes, and comply with regulatory standards. Temperature switches play a vital role in monitoring and controlling temperature-sensitive processes, thereby contributing to the overall productivity and reliability of industrial operations.

Importance of Temperature Switch Calibration

Why Temperature Switch Calibration is Necessary:

Temperature switch Calibration is essential for process to ensure their accuracy and reliability in temperature sensing and control. Over time, factors such as wear and tear, environmental conditions, and component aging can affect the performance of temperature switches. Calibration helps verify and adjust the switch’s response to temperature changes, ensuring it operates within specified tolerances and maintains accuracy.

Risks of Using Uncalibrated Temperature Switches:

Utilizing uncalibrated temperature switches poses various risks, including:

Inaccurate Temperature Readings: Uncalibrated switches may provide incorrect temperature measurements, leading to erroneous control actions or improper process management.

Reduced Product Quality: Temperature-sensitive processes reliant on uncalibrated switches may experience fluctuations in temperature, potentially compromising product quality and consistency.

Safety Hazards: Incorrect temperature readings from uncalibrated switches can pose safety risks, such as overheating equipment, product spoilage, or even fire hazards in extreme cases.

Compliance Issues: Industries subject to regulatory standards or quality certifications may face compliance issues if temperature switches are not calibrated, potentially leading to fines, penalties, or loss of certification.

Benefits of Properly Calibrated Temperature Switches:

Temperature switch Calibration offer several benefits, including:

Accurate Temperature Control: Calibration ensures that temperature switches provide precise and reliable temperature measurements, enabling effective control of temperature-sensitive processes.

Increased Operational Efficiency: Calibrated temperature switches contribute to the efficient operation of equipment and processes by minimizing temperature fluctuations and reducing energy consumption.

Compliance Assurance: Calibrated temperature switches help industries meet regulatory requirements and quality standards, ensuring adherence to safety and operational guidelines.

Extended Equipment Lifespan: Proper calibration can prolong the lifespan of temperature switches and associated equipment by preventing unnecessary wear and damage caused by temperature-related issues.

Temperature switch Calibration Procedure

Preparation before Temperature switch Calibration:

Gathering Necessary Equipment and Tools: Collect all required equipment and tools for calibration, including temperature probes, reference standards, calibration software, and documentation forms.

Ensuring Safety Measures are in Place: Prioritize safety by ensuring that appropriate personal protective equipment (PPE) is available, and follow safety protocols, especially when working with electrical equipment or in potentially hazardous environments.

Initial Inspection of the Temperature Switch:

Checking for Any Physical Damage or Defects: Inspect the temperature switch visually for any signs of physical damage, corrosion, or wear that could affect its performance during calibration.

Setting Up the Temperature switch Calibration Equipment:

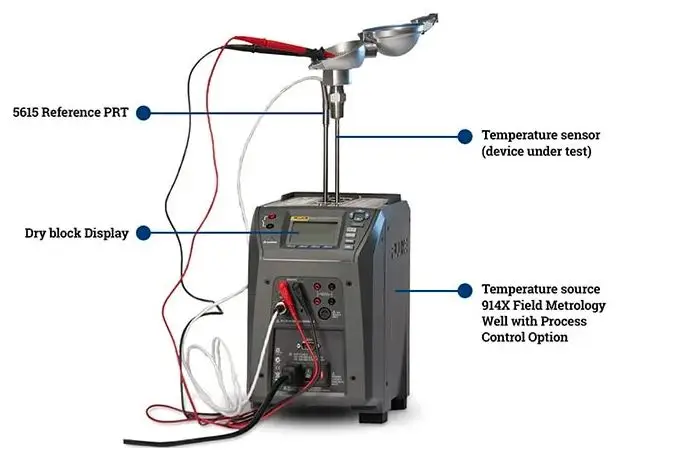

Selection of Suitable Calibration Equipment: Choose the appropriate calibration equipment based on the type and specifications of the temperature switch being calibrated. This may include temperature baths, dry blocks, or other calibration instruments.

Ensuring the Calibration Equipment is Within its Calibration Period: Verify that the calibration equipment itself is calibrated and within its valid calibration period to ensure accurate calibration results. General Items required for calibration.

- Multimeter

- Temperature bath

- Reference RTD

Performing the Calibration:

Adjusting the Temperature Switch to a Known Reference Temperature: Place the temperature switch in the calibration equipment and adjust it to a known reference temperature. This reference temperature should be within the operating range of the temperature switch.

Recording Temperature Readings and Any Adjustments Made: Record the temperature readings displayed by both the temperature switch and the reference standard. Make any necessary adjustments to the temperature switch to ensure its readings align with the reference temperature.

Follow these steps for Temperature switch Calibration

- Ensure you obtain a valid permit to work and obtain necessary approvals for the job.

- Properly isolate both cables from each other by applying PVC tape.

- Only remove the temperature switch if the process is online. Don’t remove the thermocouple.

- Insert the temperature switch into the temperature bath. Additionally, insert an RTD into the same temperature bath. This additional RTD confirms the temperature in the bath, serving as a backup to verify the temperature reading displayed by the bath.

- Attach the multimeter’s lead to the contacts of the temperature switch as per the field connections, and set the multimeter to continuity mode.

- Initially, set the temperature in the temperature bath close to the ambient temperature.

- Gradually decrease the temperature in the bath to just a few degrees (approximately 4-5 % of the setpoint) below the temperature switch’s setpoint. For instance, if the setpoint is 80 degrees Celsius, set the bath temperature to 75 degrees Celsius.

- Wait until both the temperature bath’s display and the RTD show a reading of 75 degrees Celsius. Increase the temperature by 1 or 2 degree Celsius and wait for it to stabilize.

- Repeat the process of increasing the temperature by 1 or 2 degree Celsius and waiting for stabilization until the temperature switch’s contact changes. Note down the temperature at which this change occurs. Additionally, measure the resistance of the contact in both open and closed conditions. If the resistance in the closed contact exceeds 1 ohm, consider replacing the temperature switch.

- Reset the temperature switch by decreasing the temperature value by 1 degree Celsius and observing any contact changes. Note down the temperature at which the switch triggers.

- Calculate the error percentage or use the provided calibration format to fill in all data. If the error exceeds the desirable limit as per the datasheet, calibration is required. Proceed to the next step for calibration. If the error percentage is acceptable, the temperature switch is deemed okay.

- To calibrate the temperature switch, locate the rotary knob / adjustment point provided on most temperature switches. Adjust the knob as per the manufacturer’s instructions to increase or decrease the set temperature.

- After setting the temperature, repeat steps for testing purposes.

Verification and Validation of Temperature switch Calibration Results:

Comparing Calibrated Readings with Known Standards: Compare the calibrated readings of the temperature switch with the known reference standards to verify its accuracy and precision.

Ensuring the Temperature Switch Meets Accuracy Requirements: Confirm that the temperature switch meets the accuracy requirements specified by regulatory standards or industry guidelines.

Documentation and Certification:

Recording Calibration Data and Results: Document all calibration data, including initial and final temperature readings, adjustments made, and any observations during the calibration process.

Issuing Calibration Certificates: Generate calibration certificates to provide documented evidence of the temperature switch’s calibration status and compliance with standards. Include all relevant information, such as calibration date, technician’s name, equipment used, and calibration results.

Best Practices for Calibration

Regularity of Temperature switch Calibration:

Establish a Calibration Schedule: Implement a regular calibration schedule based on manufacturer recommendations, industry standards, and regulatory requirements. Frequency of calibration should consider factors such as usage frequency, environmental conditions, and criticality of temperature measurements.

Adhere to Scheduled Calibrations: Ensure temperature switches are calibrated at the specified intervals without delay to maintain accuracy and reliability in temperature sensing and control.

Proper Handling and Storage of Temperature Switches:

Handle with Care: Handle temperature switches with care to avoid physical damage or contamination that could affect their performance.

Store in Suitable Conditions: Store temperature switches in appropriate environments with controlled temperature and humidity levels to prevent degradation or deterioration. Use protective packaging or storage containers when not in use to minimize exposure to dust, moisture, or other contaminants.

Importance of Trained Personnel for Calibration:

Qualified Calibration Technicians: Ensure calibration procedures are performed by trained and competent personnel with knowledge of temperature measurement principles, calibration techniques, and safety protocols.

Regular Training and Certification: Provide ongoing training and certification programs for calibration technicians to stay updated on the latest techniques, equipment, and standards in temperature calibration.

Documented Procedures: Develop standardized calibration procedures and documentation guidelines to ensure consistency and accuracy in calibration processes. Emphasize the importance of following procedures meticulously to maintain calibration integrity and traceability.

By following these best practices, organizations can uphold the accuracy, reliability, and compliance of temperature switches, contributing to efficient operations and quality assurance in various industries.

ISO 17025:2017 Standard for testing and calibration laboratories

ISO 17025:2017 is an internationally recognized standard that specifies the general requirements for the competence of testing and calibration laboratories. Here are some important points regarding ISO 17025:2017:

- Scope: ISO 17025:2017 outlines requirements applicable to all laboratories performing testing and/or calibration activities, regardless of the number of personnel or the extent of the scope of testing and calibration activities.

- Management Requirements: The standard emphasizes the importance of having a quality management system (QMS) in place to ensure effective operation and control of laboratory activities. This includes document control, management review, corrective actions, and continual improvement.

- Technical Requirements: ISO 17025:2017 specifies technical requirements related to factors such as personnel competence, equipment calibration and maintenance, testing methods, sampling, handling of test items, and reporting of results.

- Impartiality and Confidentiality: The standard mandates that laboratories must demonstrate impartiality and ensure confidentiality in all aspects of their operations. This includes avoiding conflicts of interest and protecting the confidentiality of client information.

- Traceability of Measurement: Laboratories must ensure the traceability of measurement results to recognized national or international standards. This involves establishing and maintaining an unbroken chain of comparisons to stated references.

- Validity and Reliability of Results: ISO 17025:2017 requires laboratories to demonstrate the validity and reliability of their testing and calibration results through the use of validated methods, proper equipment, and competent personnel.

- Proficiency Testing: Laboratories are encouraged to participate in proficiency testing programs to assess their competence and compare their performance with other laboratories. This helps ensure the reliability and consistency of test results.

- Accreditation: While ISO 17025:2017 provides requirements for laboratory competence, accreditation is a formal recognition by an accreditation body that a laboratory meets these requirements. Accreditation enhances the credibility and acceptance of a laboratory’s test and calibration results.

- Continual Improvement: Laboratories are expected to continually improve their processes, procedures, and quality management systems to enhance their overall performance and meet changing customer needs and technological advancements.

- Compliance with Legal and Regulatory Requirements: Laboratories must comply with relevant legal and regulatory requirements applicable to their testing and calibration activities, including those related to health, safety, and environmental protection.

Adhering to ISO 17025:2017 helps laboratories demonstrate their competence, enhance customer confidence, and facilitate acceptance of their test and calibration results on a national and international level.

Refer: NAMUR standard for transmitters

Conclusion

Recap of the Significance of Temperature switch Calibration:

Calibration plays a crucial role in ensuring the accuracy and reliability of temperature switches. By calibrating temperature switches regularly, we can verify their performance and ensure that they provide accurate temperature measurements, contributing to the efficiency and safety of various industrial processes.

Importance of Following Proper Temperature switch Calibration Procedures

It is essential to adhere to proper Temperature switch Calibration procedures to maintain the integrity and accuracy of temperature switches. Following standardized calibration procedures helps minimize errors, ensure consistency, and comply with regulatory requirements, ultimately enhancing the reliability and effectiveness of temperature sensing and control systems.

Encouragement for Temperature switch Calibration for Accurate Temperature Measurements:

We encourage the continuous maintenance of calibrated temperature switches to ensure accurate temperature measurements and reliable operation of industrial processes. By prioritizing calibration and regular maintenance, we can minimize risks, optimize performance, and uphold safety standards, ultimately contributing to the success and efficiency of our operations.

Temperature Switch Calibration | FAQ |

Question: What is temperature switch calibration?

Answer: Temperature switch calibration is the process of verifying and adjusting the accuracy of temperature switches to ensure they provide reliable temperature measurements and operate within specified tolerances.

Question: Why is temperature switch calibration important?

Answer: Calibration is important to ensure that temperature switches accurately detect temperature changes and trigger appropriate control actions. This helps maintain process integrity, product quality, and safety.

Question: How often Temperature switch Calibration should required?

Answer: The frequency of Temperature switch Calibration depends on factors such as the criticality of the temperature measurement, environmental conditions, and regulatory requirements. Typically, temperature switches are calibrated annually or as recommended by manufacturers or industry standards.

Question: What are the consequences of using uncalibrated temperature switches?

Answer: Using uncalibrated temperature switches can lead to inaccurate temperature readings, resulting in improper process control, compromised product quality, safety hazards, and non-compliance with regulatory standards.

Question: How is temperature switch calibration performed?

Answer: Temperature switch calibration involves comparing the readings of the temperature switch with known reference temperatures using calibrated equipment such as temperature baths or dry blocks. Adjustments are made to the temperature switch as necessary to ensure accuracy.

Question: Can I calibrate temperature switches in-house, or should I use a third-party calibration service?

Answer: Both options are viable. In-house calibration requires proper equipment, trained personnel, and adherence to calibration procedures. Third-party calibration services offer expertise, traceability, and accreditation, ensuring compliance with standards and regulations.

Question: What are the steps involved in temperature switch calibration?

Answer: The calibration process typically includes preparation, inspection of the temperature switch, setting up calibration equipment, performing calibration, verifying results, and documenting findings. Each step is crucial for ensuring accuracy and traceability.

Question: How can I tell if my temperature switch needs calibration?

Answer: Signs that indicate a temperature switch may need calibration include inconsistent temperature readings, frequent false triggers or failures to trigger, changes in process conditions, or deviations from expected performance.

Question: What should I do if my Temperature switch Calibration fails?

Answer: If a temperature switch fails calibration, it may require adjustment, repair, or replacement, depending on the nature of the issue. Consult with calibration experts or manufacturers for guidance on corrective actions.

Question: Is calibration traceability important for temperature switch calibration?

Answer: Yes, calibration traceability ensures that the calibration process is documented, and measurements are traceable to national or international standards. This enhances the reliability and credibility of calibration results.